After Sales

INSPECTION & TEST SERVICES

- Examination of documents

- Design features Control

- Tank internal Control

- Tank external Control

- Hydraulic pressure test

- Vacuum testing

- Leak Testing

- Water capacity Determination

- Service equipment Inspection

- Steel construction Frame inspection

- Mechanical tests

- Non-Destructive Testing

- Test report, certification and marking control

- As a result of the checks and tests made, Intermediate or Periodic Examination Certificate is issued by the local authority TSE.

- Visual inspection of tanks and equipment.

- Functional testing of valves and other accessories.

- Leak testing

- Vacuum measurement

- Assessment of any changes in the installation and operating conditions of the environment

- Safety valves are dismantled to check on / off pressures

- The accredited organization supervision and periodic control report In case of a request for the outcome of controls and tests made

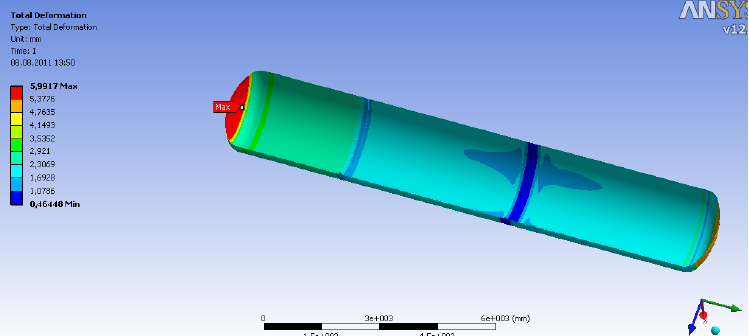

Taking into account the relevant damage mechanisms, Life-cycle studies are carried out by Cryocan engineering team work on the basis of units and plants or on the basis of equipments.

In industrial plants, the equipments, during service-life, are exposed to fatigue and damage due to the loads (pressure, vibration, etc.) and operating conditions (temperature, corrosive environment, etc.). On the basis of the equipment or the plant, the risk assessments and the possible damage mechanisms are examined and the control calculations and service-life calculations are made and reported. Life-cycle determinations are mainly applied to waste heat boilers, steam lines, static equipment operating under high temperature and pressure in power plants. Damage mechanisms to be considered;

- Thermal Fatigue

- Thermo Mechanical Fatigue

- Wear and Corrosion

- Creep

- Thermal Aging

The safety measures that are not taken in the equipments which are operated by electricity may cause the loss of life and property.To ensure the safe and continuous use of the electrical installations and systems, the periodical control and tests of the electrical equipments and installations are done.

Our Cryocan technical service team performs periodic checks with our Electrical Engineers in this area and corrects problems with the necessary corrective and preventive actions in case of inconvenience.

- Electrical Installation Compliance Controls

- Grounding Measurements

- Lightning Rod Installation Measurements

- Cathodic Protection Measures

- Electric Panels Thermal Camera Measurements

- Stray Current Relay Controls

Coating, paint checks and error analyzes conducted by Cryocan technical service team ensure that your assets are protected and that prospective corrosion-resistant lines are avoided.

Controls are carried out with our NACE certified Level 2 personnel and our calibrated dye control devices. Failure Mode and Effects Analysis (FMEA) are done and the result is reported by our paint specialists.

- Post-paint coating thickness, hardness, durability and color tests

- Pre-paint surface checks

- Paint application supervision

- Paint damage checks and analyzes

- Holiday tests

MAINTENANCE AND REPAIR

Cryocan technical service team undertakes turnkey maintenance of storage tanks, pressure vessels, pipelines, heat exchangers, steam boilers, waste heat boilers and all related equipments of LNG, LPG, LIN, LAR, LOX, LCO2, FUEL OIL, NH3 and etc.

Partaking in storage facilities, chemical plants and mining facilities. Maintenance and overhaul may include inspection activities, analyzes, tests and sourced repair. We undertake and manage all processes on a turnkey basis.

- Welded Repair Activities

- Head and Shell Repair

- Manhole and Nozzle Revisions

- Line Repair Activities

- Spool Manufacturing and Assembly

- Leak Repair

- Vacuum Measurement and Vacuum Process

- Calibration of measuring instruments

- Non-Destructive Testing

- Thickness Measurements

- Sandblasting & Painting

As Cryocan technical service team, we carry out the periodic testing and maintenance of the safety valves and pressure vacuuming vents which are used to protect the equipment pipeline under internal pressure by vacuum.

The maintenance activities are certified with the participation of the surveillance companies if requested. In addition to the maintenance certificate, surveillance firms are given testimony certificates at the end of the work to our customers.

The difference we have with Cryocan is that only the tests of the valves should be carried out by carrying out repair activities in the areas of possible leakage and operation. Main activities are described below.

Safety Valves ;

- Dismantling and Cleaning Activities

- Control of seating surfaces and repair

- Spring mechanism corrosion and fatigue checks

- Leak tests and set pressure applications

- Marking and painting

Pressure Vacuum Valves;

- Dismantling and Cleaning Activities

- Weight controls

- Set value controls

- Labeling and painting

Valves;

- Dismantling and Cleaning Activities

- Control of seating surfaces and repair

- Functionality Tests