SKID SYSTEMS

MAIN CHARACTERISTICS

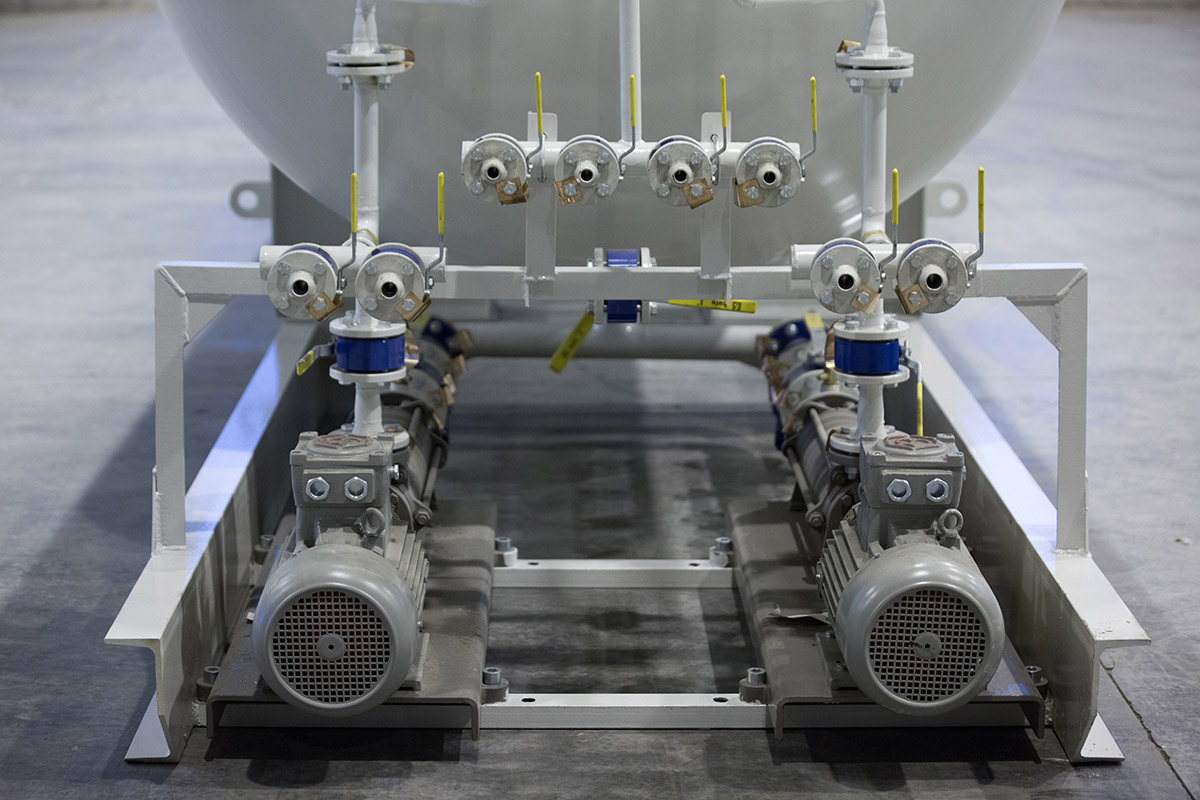

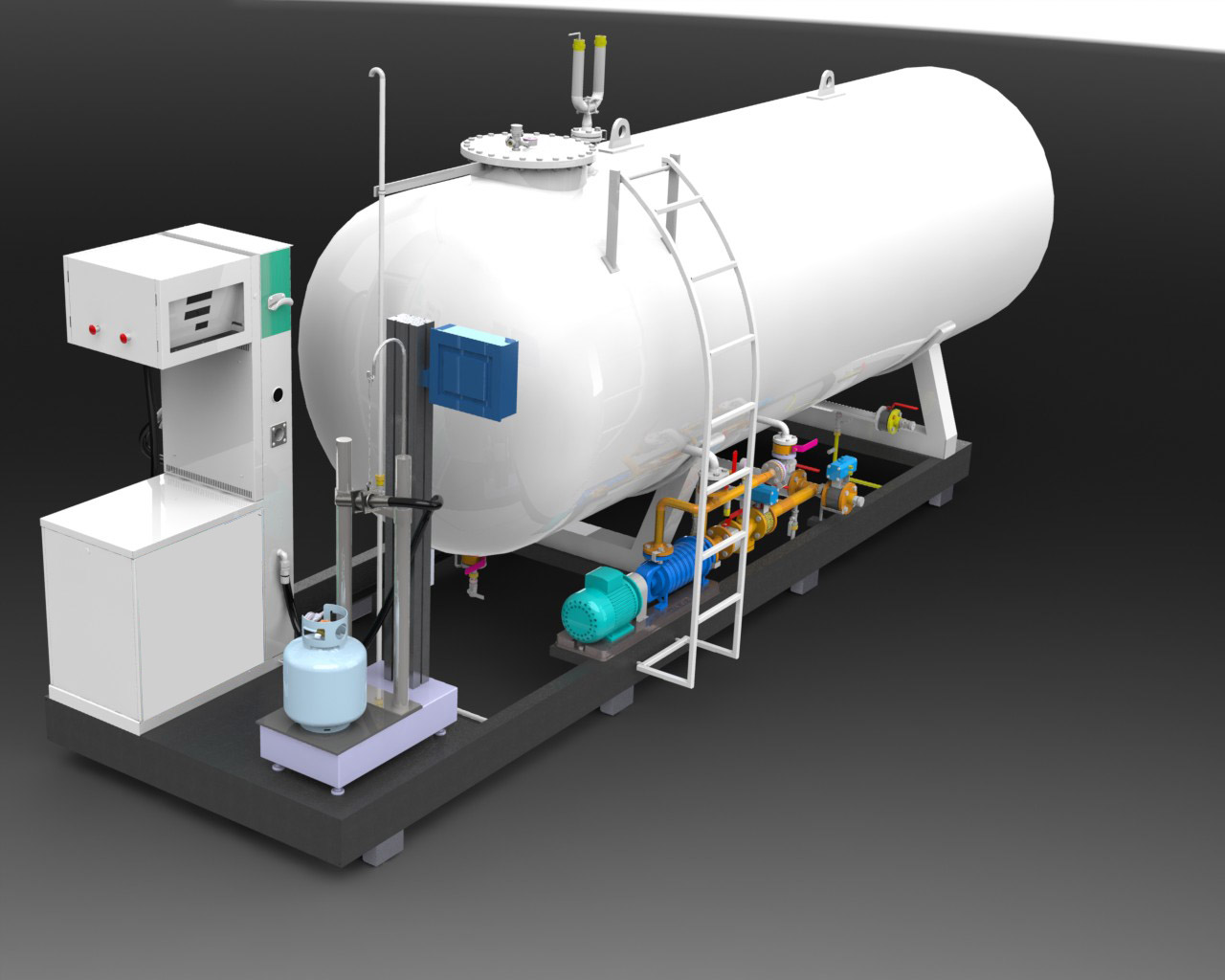

LPG AUTOGAS SKID SYSTEM

• Manufacturing in association with EN 13445, AD 2000 Code, EN 12542, ASME (U STAMP), GOST and 2014/68/ EU Pressure Equipment Directive (PED)

• High quality paint application by using oven-drying

• High range of storage capacities as per customer requirement

• Tank design enabling a great convenience in shipping

• Non-destructive inspection methods in accordance with standards (Radiographic test, Penetrant test, Magnetic Particle Test, etc.)

40’ MOBILE FUEL SYSTEM

• Standard 40’ ISO Container

• 40 m³ Prismatic Double wall tank

• 2 nozzle dispenser

• ATEX MID certification

• 30 m³ Ex-proof Pump

• Electronic Digital Displa

LPG MOBILE BOTTLING SYSTEM

• 5m³, 10m³, 15m³ and 20m³ Gross Capacity

• 2 scales (Mechanic or Electronic) for 12,5 kg and + 50kg

• Ready to use system

LPG AUTOGAS TANKS

| TYPE | CAPACITY | LENGTH | WIDTH | HEIGHT |

|---|---|---|---|---|

| CCSTR10LPG | 10 m³ | 5400 mm | 1600 mm | 1850 mm |

| CCSTR22LPG | 22 m³ | 5810 mm | 2350 mm | 2835 mm |

| CCSTR35LPG | 35 m³ | 8710 mm | 2300 mm | 2650 mm |

• Flexibility in design to satisfy the clients’ requirements and alternative needs

• Optional design in line with the conditions of the operation territory

• Perfect ergonomic design in management service

DESIGN CONDITIONS

| Design Code | : AD 2000 Code, EN 13445, EN 12542 ASME (U STAMP) and GOST |

| Design Pressure | : 18 bar |

| Design Temperature | : -50 °C / +60 °C |

| Material | : In accordance with design codes |

| Radiographic Control | : In accordance with design codes |

| Liquid Penetrant Testing | : In accordance with design codes |